Mining Industry Projects and Services Specialists such as "Trolley Assist Hauling System"

With years of experience in electrification projects in the mining industry, our team can offer valuable recommendations and expert advice in all phases of the life cycle of these systems.

We are proud to be trusted partners in the transition to more sustainable and cost-efficient mining.

Our company is proud to have extensive experience in the design, implementation, operation and maintenance of systems such as Trolley Assist for the mining industry.

We have worked on diverse projects, facing technical challenges and achieving successful results for our clients.

Advantages of the System for Optimizing the Use of Cargo Trucks

Reduction of Fuel Consumption

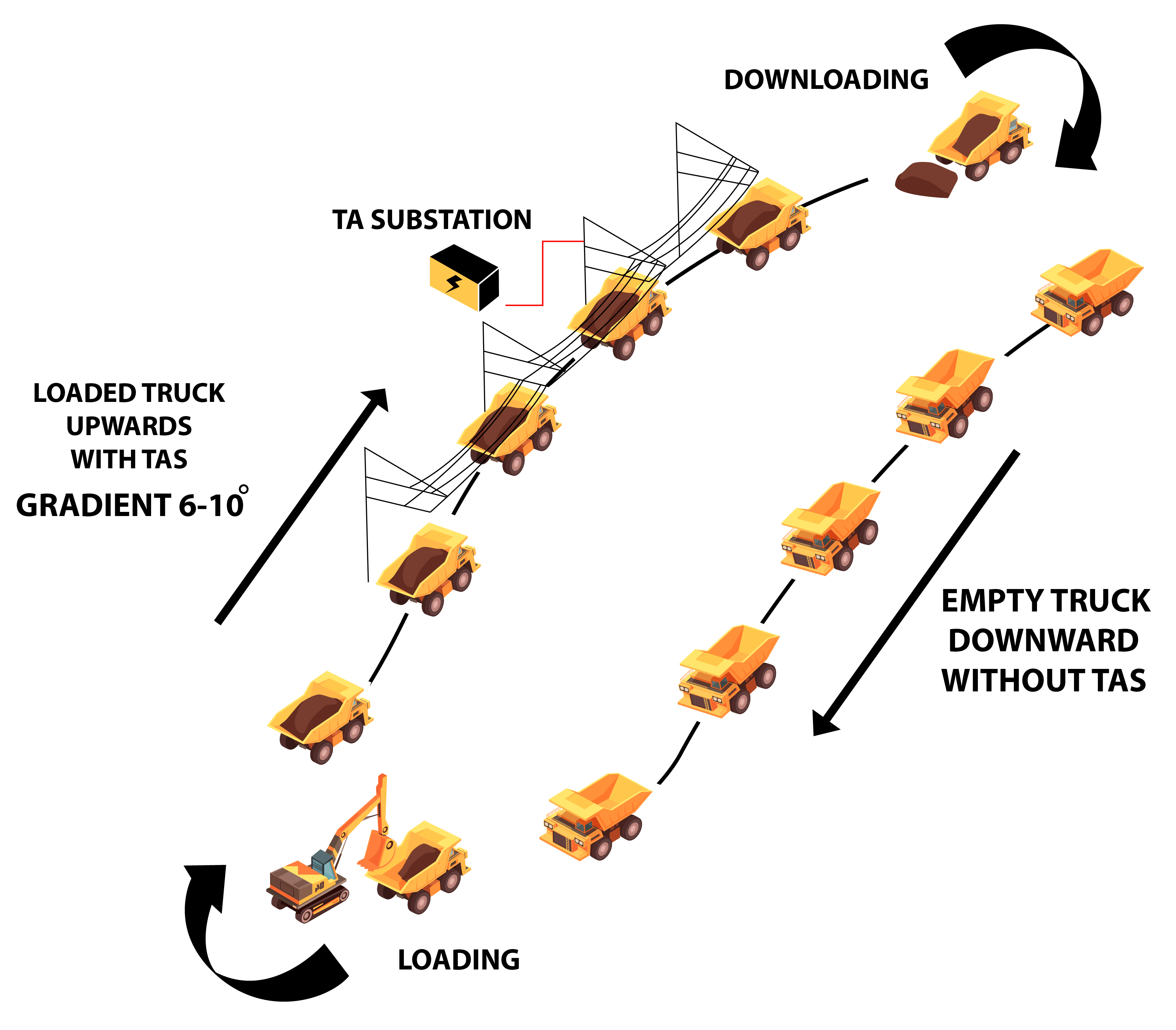

The Trolley Assist uses electrical overhead lines to power cargo trucks as they operate inside the mine. This eliminates the need for diesel engines, significantly reducing fuel consumption and greenhouse gas emissions.

Increase of the Efficiency

The electric power provided by Trolley Assist allows freight trucks to operate at higher speeds and with greater power, improving their productivity and loading capacity. This optimizes the flow of materials within the mine and reduces cycle times.

Greater Durability

Eliminating diesel engines and reducing vibrations and stress on the vehicle extends the life of freight trucks, reducing maintenance costs and replacement needs.

Reduction of Fuel Consumption and Emissions

1 Environmental Benefits

2 Noise Reduction

3 Greater Security

4 Reputation Boost

Advice on Implementation, Operation and Maintenance

1Planning and Design

3Operation and Maintenance

2Installation and Commissioning

4Continuous Optimization

Technical Consultant with Improvement Recommendations

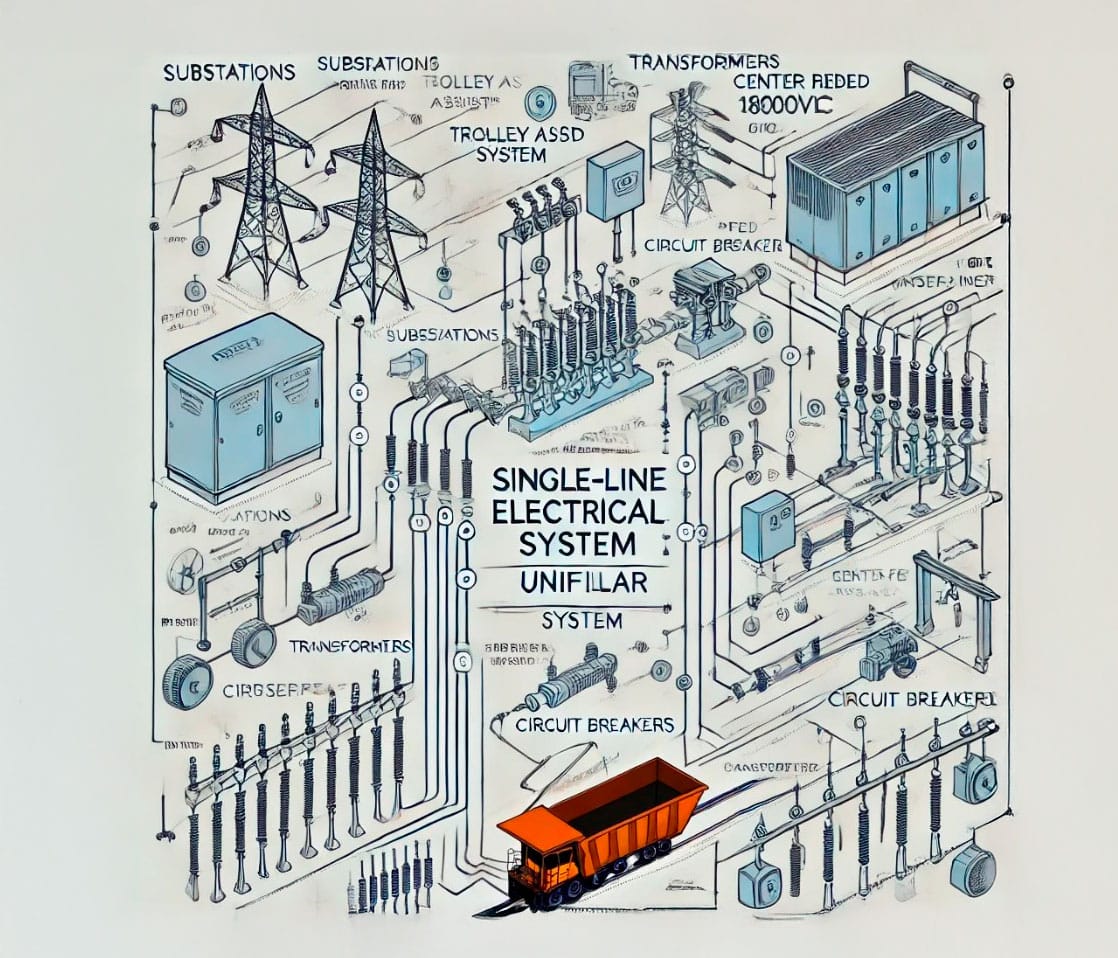

Design of Electrification Systems

Cost and Sustainability Benefits

Fuel Cost Reduction

Reduction of Emissions

Greater Operational Efficiency

Reputation Improvement

Technical and Implementation Challenges

The design and installation of overhead power lines, the integration of the Trolley Assist system with cargo trucks, the safety of the operation and maintenance of the system.

The initial investment in the Trolley Assist infrastructure, staff training, coordination with other mine teams and adaptation to the geographical and climatic conditions of the mining site.

Mining Projects and their Electrification

Experience and Specialized Knowledge

Team of Experts: Our company is proud to have a technical team specialized in electrification, capable of providing customized solutions for each mining project. These experts have in-depth knowledge of Trolley Assist systems and can advise our clients at all stages, from initial design to implementation and long-term maintenance.

Our comprehensive approach allows us to understand the specific needs of each mining operation and develop tailored solutions. We work closely with our customers to identify technical challenges and find the best ways to optimize the use of freight trucks, reduce fuel consumption and polluting emissions.

With years of experience in electrification projects in the mining industry, our team can offer valuable recommendations and expert advice in all phases of the life cycle of these systems. We are proud to be trusted partners in the transition to more sustainable and cost-efficient mining.

Design, Implementation and Maintenance: Our company is proud to have extensive experience in the design, implementation, operation and maintenance of Trolley Assist systems for the mining industry. We have worked on diverse projects, facing technical challenges and achieving successful results for our clients.

Our team of technical experts is highly trained in all stages of the life cycle of these systems, from initial design to long-term operation and maintenance. We provide specialized advice and recommendations to optimize the use of cargo trucks, reduce fuel consumption and polluting emissions.

We are proud to be trusted partners in the electrification of mining projects, helping our customers achieve their sustainability and cost efficiency goals. Our comprehensive approach and vast experience allow us to deliver tailored solutions that perfectly fit the needs of each mining operation.